Moving Coil Galvanometer Investigatory Project PDF Class 12

Introduction

A galvanometer is an electromechanical instrument for detecting and indicating electric current. A galvanometer works as an actuator, by producing a rotary deflection (of a “pointer”), in response to electric current flowing through a coil in a constant magnetic field. Early galvanometers were not calibrated, but their later developments were used as measuring instruments, called ammeters, to measure the current flowing through an electric circuit. Galvanometers developed from the observation that the needle of a magnetic compass is deflected near a wire that has electric current flowing through it, first described by

Hans Oersted in 1820. They were the first instruments used to detect and measure small amounts of electric currents. André-Marie Ampère, who gave mathematical expression to Oersted’s discovery and named the instrument after the Italian electricity researcher Luigi Galvani, who in 1791 discovered the principle of the frog galvanoscope – that electric current would make the legs of a dead frog jerk. Sensitive galvanometers have been essential for the development of science and technology in many fields. For example, they enabled long range communication through submarine cables, such as the earliest Transatlantic telegraph cables, and were essential to discovering the electrical activity of the heart and brain, by their fine measurements of current.

Principle

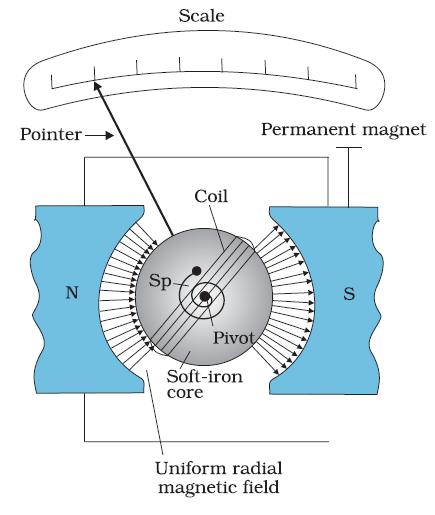

The Principle of moving coil galvanometer is based on the interaction between a magnetic field and a current-carrying coil. The galvanometer consists of a lightweight coil of wire suspended within the field of a permanent magnet. When an electric current flow through the coil, it experiences a torque due to the magnetic force acting on it, according to Ampere’s law. This torque causes the coil to rotate, and the degree of rotation is directly proportional to the current passing through the coil. To measure this rotation, a thin pointer attached to the coil indicates the current on a calibrated scale. The sensitivity of the moving coil galvanometer can be adjusted by varying factors such as the strength of the magnetic field or the number of turns in the coil. This instrument is widely used in applications where precise current measurements are essential, such as in laboratories and electrical testing environments.

Construction

It consists of a rectangular coil of thin insulated copper wires having a large number of turns. The horseshoe magnet has cylindrically concave pole-pieces. Due to this shape, the magnet produces radial magnetic field so that when coil rotates in any position its plane is always parallel to the direction of magnetic field. When current flows through the coil it current flows through the coil it gets deflected. A gets deflected. A soft iron cylinder is fixed inside the coil such that the coil can rotate freely between the poles and around the cylinder. Due to the high permittivity, the soft iron core increases the strength of the radial magnetic field.

Sensitivity of Galvanometer

The current sensitivity of a galvanometer is defined as the deflection produced when unit current passes through the galvanometer. A galvanometer is said to be sensitive if it produces large deflection for a small current.

There are two types of sensitivity:

- Current Sensitivity

- Voltage Sensitivity

How to increase Sensitivity of Moving Coil Galvanometer?

Following are the parameters which help in increasing sensitivity of moving coil galvanometer:

- Number of turns (n) of the coil

- Area of the coil (A)

- Magnetic induction (B)

- Couple per unit twist of the suspension fibre (k)

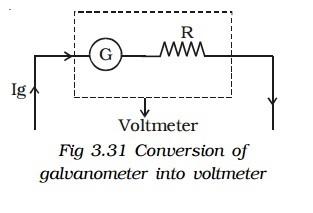

Conversion of Galvanometer into Voltmeter

Voltmeter is an instrument used to measure potential difference between the two ends of a current carrying conductor. A galvanometer can be converted into a voltmeter by connecting a high resistance in series with it. The scale is calibrated in volt. The value of the resistance connected in series decides the range of the voltmeter.

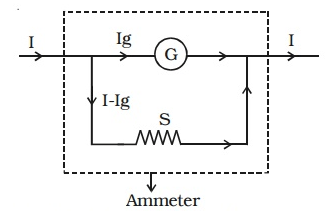

Conversion of Galvanometer into Ammeter

A galvanometer is a device used to detect the flow of current in an electrical circuit. Even though the deflection is directly proportional to the current, the galvanometer scale is not marked in ampere. Being a very sensitive instrument, a large current cannot be passed through the galvanometer, as it may damage the coil. However, a galvanometer is converted into an ammeter by connecting a low resistance in parallel with it. As a result, when large current flows in a circuit, only a small fraction of the current passes through the galvanometer and the remaining larger portion of the current passes through the low resistance. The low resistance connected in parallel with the galvanometer is called shunt resistance.

Advantage of Moving Coil Galvanometer

- Accuracy: They provide accurate measurements due to their sensitivity and precise construction.

- Linear Response: The deflection of the coil is directly proportional to the current passing through it, resulting in a linear response. This feature is beneficial for accurate measurements.

- Low Power Consumption: Moving coil galvanometers typically consume very little power, making them suitable for applications where power efficiency is important.

- Wide Frequency Response: They can measure both direct current (DC) and alternating current (AC) effectively, providing versatility in various applications.

- Compact Design: Moving coil galvanometers can be designed in a compact size, making them suitable for applications with limited space.

- No Hysteresis: Moving coil galvanometers typically do not exhibit hysteresis, meaning their readings are not affected by the previous history of the system.

- Durability: With proper construction and materials, these galvanometers can be durable and withstand regular use in different environments.

Disadvantage of Moving Coil Galvanometer

The moving coil galvanometer is a sensitive instrument used for detecting and measuring small electric currents. However, like any device, it has its disadvantages. Here are some disadvantages of a moving coil galvanometer:

- Limited Range: Moving coil galvanometers are designed to measure small currents, and their range is typically limited. They may not be suitable for measuring larger currents without the use of external shunt resistors.

- Inertia: The moving coil has mass and inertia, which means it takes some time to respond to changes in current. This can result in a delay in the galvanometer’s indication, especially when measuring rapidly changing currents.

- Friction and Damping Issues: Friction between the moving parts and the coil may affect the accuracy and responsiveness of the galvanometer. Damping mechanisms are often employed to minimize oscillations, but these can also introduce some errors.

- Accuracy Affected by Magnetic Fields: External magnetic fields can influence the accuracy of the moving coil galvanometer. It is susceptible to stray magnetic fields, which can cause deviations in the readings.

- Temperature Sensitivity: The accuracy of the galvanometer can be affected by changes in temperature. Temperature variations can cause expansion or contraction of materials, influencing the dimensions and performance of the instrument.

Conclusion

In conclusion, the moving coil galvanometer is a valuable instrument in electrical measurements, providing accurate and sensitive readings of small electric currents. Its conversion into voltmeter and ammeter further extends its versatility in various applications. While it offers several advantages, including accuracy, linear response, and low power consumption, there are certain limitations such as a limited range and susceptibility to external factors.

To ensure reliable and precise measurements with a moving coil galvanometer, it is essential to follow precautions such as careful handling, avoiding strong magnetic fields, and maintaining proper calibration. Regular maintenance and attention to environmental conditions contribute to the durability and longevity of the instrument.

Overall, the moving coil galvanometer continues to play a crucial role in scientific and technological advancements, contributing to the understanding and measurement of electric currents in diverse fields.

Precaution

- The moving coil galvanometer is a sensitive instrument with delicate components. Handle it with care to avoid damage or misalignment.

- Keep the galvanometer away from strong external magnetic fields as they can interfere with its readings. Ensure a clean and magnetically neutral environment.

- Vibrations can affect the accuracy of the galvanometer readings. Place the instrument on a stable surface and minimize any vibrations in the surroundings.

- Maintain a stable temperature environment. Avoid exposure to extreme temperatures that may cause expansion or contraction of materials, impacting the performance of the galvanometer.

- Calibrate the galvanometer regularly to ensure accurate readings. Perform periodic checks to verify its calibration and functionality.

- Protect the galvanometer from exposure to water or other liquids. Moisture can damage the delicate internal components.

- If converting the galvanometer into a voltmeter or ammeter, follow the recommended procedures and use appropriate resistances. Incorrect conversions can lead to inaccurate readings or damage.

Bibliography

- google.com

- wikipedia.com

- https://study.com/

- https://www.electricalmaker.com/

- https://byjus.com/